Rheinmetall is launching the Rescue model of its Mission Master at CANSEC 2019. The Mission Master is a modular unmanned ground vehicle (UGV) that facilitates recovery of injured troops without compromising the operators’ safety, along with many other dangerous, dirty, and dull (DDD) tasks.

The newly released rescue variant of Rheinmetall’s flagship autonomous vehicle allows for in-field medical intervention.

This gives remotely situated soldiers the ability to evacuate casualties over long distances either autonomously or via remote control.

Rescue model: enhancing casualty care effectiveness In the field, the right equipment can be the difference between life and death for wounded soldiers, since 90% of fatalities occur between the time of trauma and arrival at the combat zone medical facility. Rheinmetall’s Rescue UGV has all the equipment necessary for a successful evacuation, including two basket stretchers with sliding provisions, head and foot immobilizers, oxygen masks and canisters, a monitor defibrillator, and a hot/cold box.

All of these items would be impossible for a medic to carry on foot, but the Mission Master can handle the load with ease. Operators can command the Mission Master from near or far using autonomous navigation, reducing the number of personnel needed on the ground.

This feature leaves medics free to focus all of their attention on the injured soldier, as opposed to wasting precious time driving back to the extraction point. While transporting a wounded soldier using the UGV’s stretcher, for example, accompanying medics can use the vehicle as a workstation to administer emergency care.

Using the “follow me” function, the UGV can roll alongside other soldiers, who are busy making sure that the surrounding area is safe and secure. In both “follow me” and autonomous navigation modes, the Mission Master significantly relieves cognitive and physical stress, allowing troops to deal with the mission at hand.

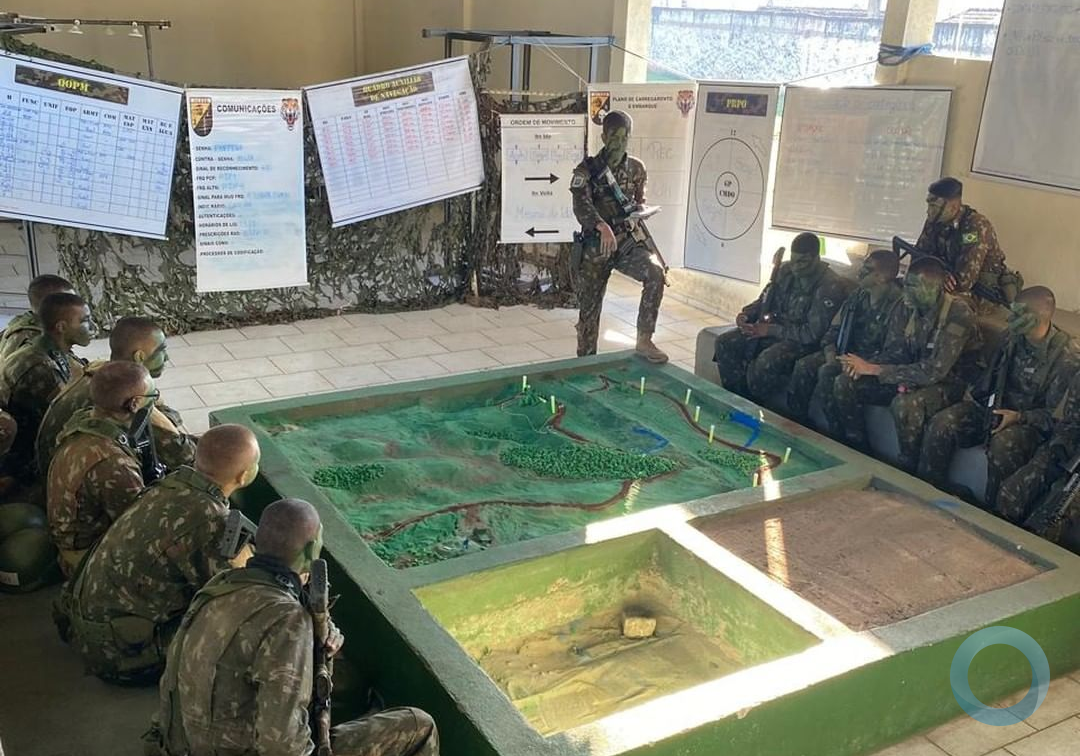

Surveillance that saves lives The Mission Master – Surveillance is designed to carry out observation and reconnaissance. Rheinmetall’s UGV is equipped with long-range EO/IR cameras, a 5-metre telescopic mast, radar, laser rangefinders (LRF), and GPS heading systems for 360-degree surveillance.

As an autonomous vehicle, the Mission Master – Surveillance can minimize the number of troops needed on the ground, while providing timely situational awareness for enhanced security and informed decision-making.

Multiple sensors relay real-time data to the integrated Rheinmetall Command and Control Software (RC2S) and Argus soldier system, enabling rapid threat detection during operation in the field. The UGV can transport much more specialized, high-performance equipment than soldiers can typically carry on their person.

As a result, not only does the Mission Master help to significantly reduce the physical load carried by dismounted soldiers, it also enhances the likelihood of mission success. The integration advantage Each version of the Mission Master is networked to both the Argus soldier system and RC2S, the Group’s command and control software.

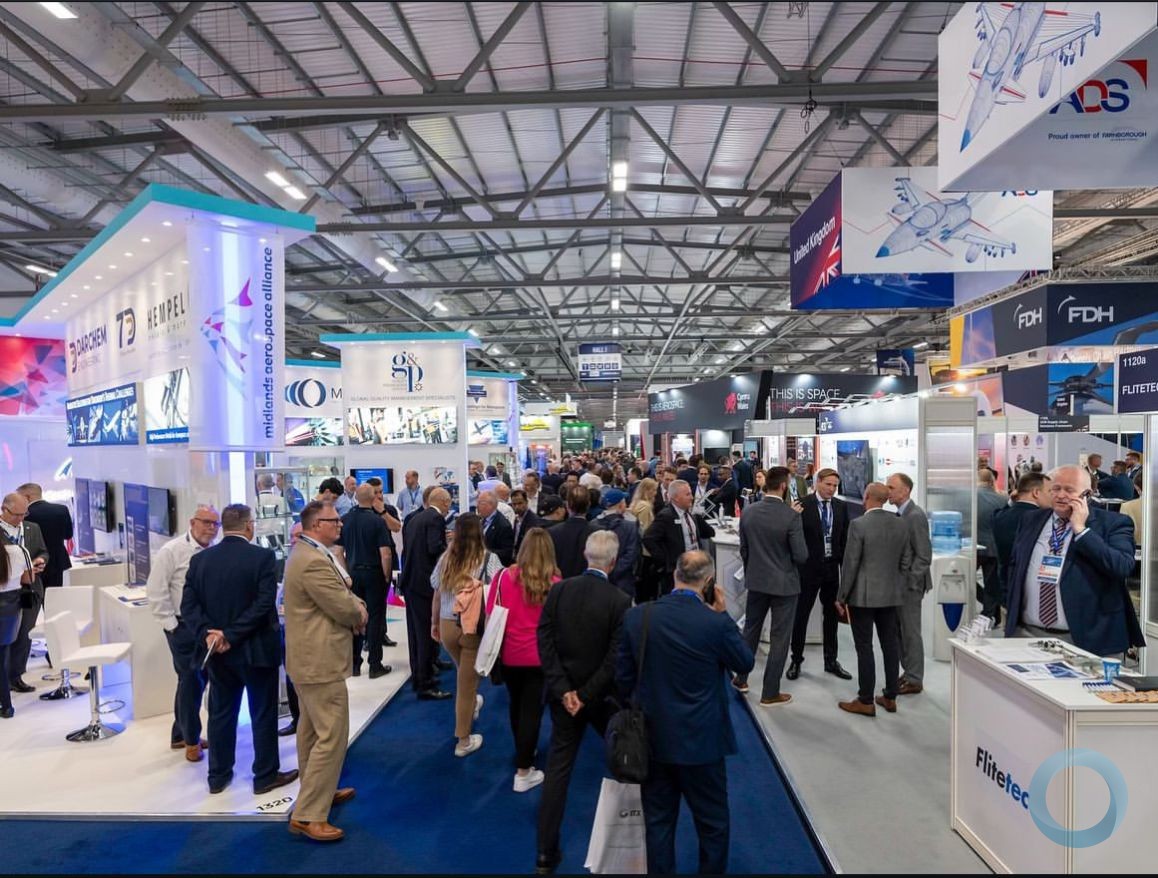

This type of integration is a Rheinmetall specialty, and will be proudly on display at this year’s CANSEC tradeshow. The rugged, ultra-portable Argus soldier system can control the UGV as well as receive data from its many sensors, delivering mission-critical information straight to soldiers’ tactical user interface.

It can also send essential reconnaissance and updates to higher echelons of command via the RC2S. Seeing is believing Nothing compares to seeing our UGV in person. At this year’s CANSEC exhibition, Rheinmetall will be showcasing the Rescue model at its outdoor booth, and the Surveillance version in its indoor booth. Don’t miss your chance to speak with our experts about the Mission Master and its many advantages!

HX 10×10 Heavy Recovery Vehicle – high off-road mobility and heavy-duty recovery capabilities

In operations both at home and abroad, modern armed forces depend on assured, round-the-clock mobility and reliable logistics. Robustness, versatility and functionality are the most important performance criteria – no matter how bad the roads or how difficult the terrain. Increasingly important, too, are flexible protection solutions, crucial for keeping crews safe during deployed operations.

The latest generation of HX vehicles from Rheinmetall MAN Military Vehicles (RMMV) meets all of these criteria. It is the outcome of decades of experience in developing, building and – by no means least – servicing military vehicles.

At CANSEC 2019, Rheinmetall is presenting its HX 10×10 Heavy Recovery Vehicle, or HRV.

This vehicle combines high off-road mobility with a heavy-duty recovery capability. It is able to recover vehicles in suspended as well as supported (underlift) tow mode. Highly mobile, the 10×10 vehicle features an underlift with a capacity of up to 15 tons as well as a recovery boom.

The recovery boom is a very versatile recovery system. It includes a crane with a lifting capability of up to 23 tons (at 60 degrees elevation fully extended), two independent winches (Rotzler HZ090) for righting vehicles, and a constant pull (capstan) main winch (Rotzler TR200). The recovery boom enables 360° operations around the recovery vehicle. The HX 10 x 10 HRV can tow a hook load of up to 15 tons. The gross train weight is 75 tons.

The HX 10×10 HRV offers a high degree of protection against ballistic, mine and IED threats when utilized with an integrated armoured cabin. Vehicles can be “fitted for but not with”. This means that they can be fitted with an integrated armoured cabin level.

The HX family – a match for modern mission scenarios

With some 10,000 vehicles now in service around the globe, the HX numbers among the world’s most widely used military trucks, with abundant operational experience. The HX family comes in variants ranging from 4×4 to 10×10, configured for a multitude of different missions: cargo trucks and heavy-duty recovery vehicles, tankers, firing units and system platforms as well as folding-road and bridge-laying systems. The engines that power these trucks are designed for outputs of up to 680 HP.

The vehicle family concept results in largely identical modes of operation, maintenance and repair as well as spare parts, leading in turn to lower lifecycle costs. Moreover, RMMV also offers full service support, all from a single source.

Adhering to a strict military-off-the-shelf (MOTS) approach, RMMV uses proven, reliably modified mass production components in the HX family, specially designed to meet military requirements. This results in made-to-measure military vehicles that deliver maximum cost-effectiveness.

A crucial characteristic of these vehicles is the robust chassis design, enabling inclusion of protected cabins. Featuring the heaviest front axle load in its class, the vehicle can handle a heavily protected driver’s cab large enough for three people.

Furthermore, the cabs can also be equipped with an optional NBC ventilation system (limited to protected cabs), integrated command and control systems, connections to soldier systems, remotely controlled weapon stations, jammers, active defence systems (ADS) and fast-acting smoke/obscurant dispensers.

From the outset, these trucks are designed not just for maximum robustness, payload capacity, mobility and an all-terrain capability, but also to operate at temperatures ranging from -32°C to +49°C. They can also be adapted to operate in all other climates: an arctic kit is available for several vehicles that enables them to operate at temperatures as low as -46°C.

It is also possible to fit them with C4I systems without major conversion work, while their electromagnetic compatibility exceeds that of all other trucks on the market.

Other special capabilities include a standard fording depth of 1.5 metres without prior preparation. Moreover, the state-of-the-art engines that power these trucks feature full F34 compatibility in accordance with the NATO single fuel concept.

Particularly in multinational operations, the worldwide presence of RMMV vehicles offers major advantages in terms of interoperability and logistics. Among others, the current list of user nations includes the UK, Australia, New Zealand and Denmark. Norway and Sweden have both placed substantial orders with RMMV as well.